Automatic real-time system for measurement of wheelsets geometrical parameters” or ”3DWheel System

Our new system is designed for contactless automatic measurement of geometrical parameters of railway wheels and can be easily installed at any type of rail infrastructure.

The system uses a combination of ten 2D laser scanners, RF625 Series mounted wayside in the track area (5 pcs for every track side) and calibrated into one common coordinate system.

A measurement cycle starts when an inductive sensor detects a wheel.

While a wheel passes through the system of synchronized 2D laser scanners, its profile is taken at many sections.

All measurement readings for all the train wheels are sent through Ethernet to control computer for profiles reconstruction and dimensions calculations. Finally all data are collected in the host depot computer in wheel sets wear database.

Video demonstration of the system is available here Real time wheels geometry measurement system page.

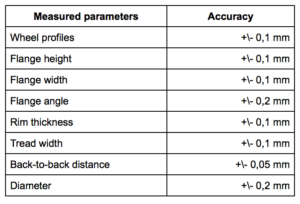

Specifications:

Please Contact Us for further information